We have 12 different hues and specifications of chrome oxide green to meet the needs of most customers.

We are not only manufacturers of chrome oxide green pigments but also providers of application solutions for chrome oxide green pigments.

CI Pigment Green 17(P.G.17)

Chrome Oxide Green (Cr₂O₃), as an inorganic green pigment, has emerged as a core coloring agent in coatings, surface layers, powder coatings, ceramics, glass, and plastics since its industrial production in the 19th century, owing to its unique chemical stability, weather resistance, and environmental compatibility. Compared to traditional organic green pigments (e.g., phthalocyanine green) or other inorganic pigments (e.g., cobalt green, chromium green complex salts), chromium oxide green demonstrates significant advantages in high-temperature tolerance, chemical corrosion resistance, and ecological compliance. Particularly under the global trend of increasingly stringent environmental regulations, its market demand continues to grow.

coating

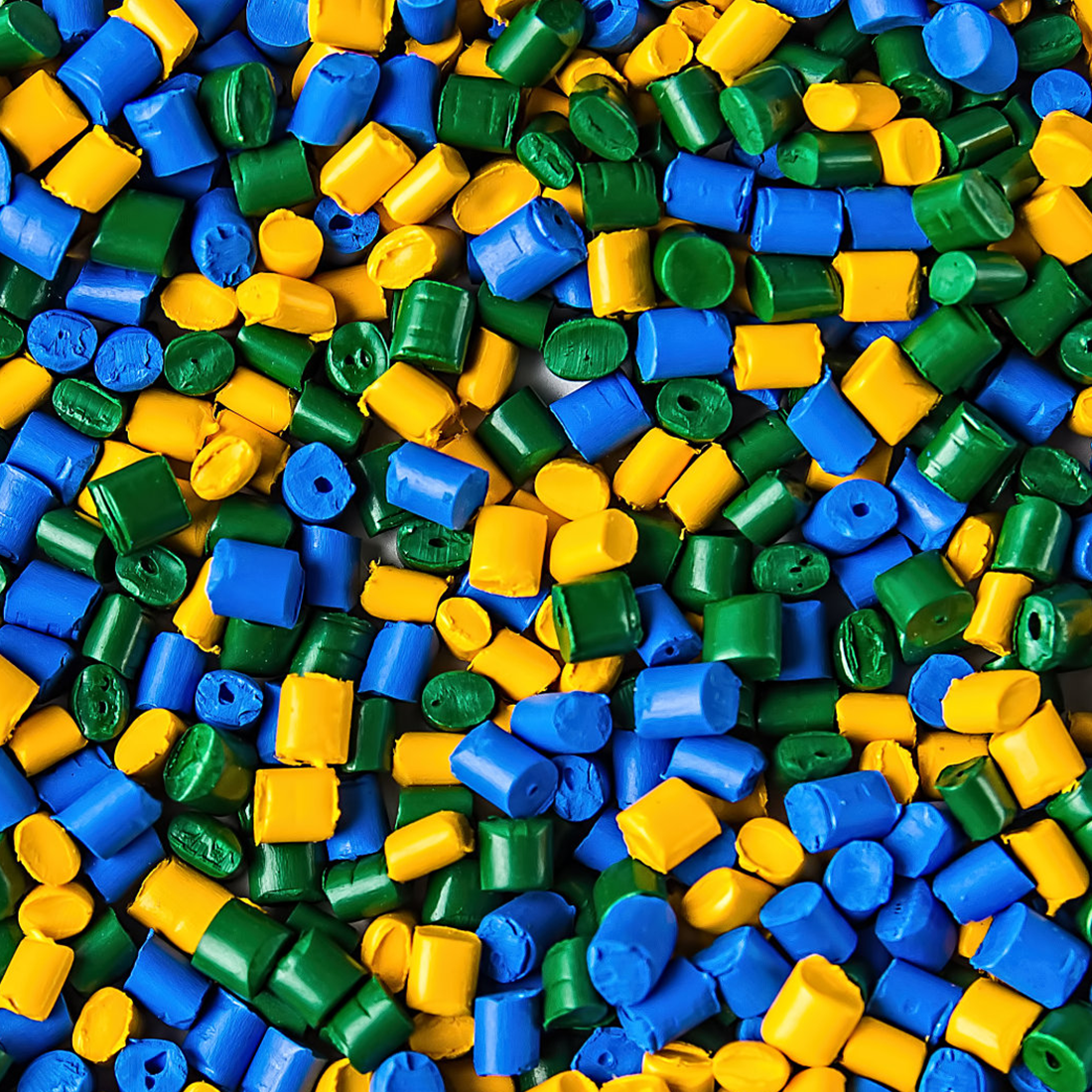

plastic

Ceramics

Makeup

Concrete

Full Spectrum Coverage: Tailored Solutions for Every Shade

Our chromium oxide green products span the entire spectrum from light green to deep green, offering a diverse palette that includes vibrant mint greens, sophisticated olive tones, and rich emerald hues. Through advanced synthesis techniques and formulation optimization, we achieve precise color control, eliminating the need for clients to source from multiple suppliers. Whether for coatings, plastics, ceramics, or inks, our comprehensive product matrix ensures seamless alignment with unique application requirements.

As adherents to international quality standards, we employ cutting-edge testing technologies and end-to-end process monitoring to guarantee color difference (DE value) ≤1 across all batches—a standard rivaling top-tier industry players. This achievement stems from our uncompromising focus on raw material purity, reaction parameter optimization, and post-treatment refinement.

Quality Benchmark: Stringent Process Control

Empowering Services with Technology, Building Trust through Strength

We deeply understand that our clients’ success is the driving force behind our progress. From R&D customization to mass production, and from color matching to technical support, our professional team consistently delivers comprehensive services with efficient responsiveness and meticulous attention to detail. Whether it’s a small-scale trial production or a large-scale order, we ensure dual guarantees in delivery timelines and product performance, empowering clients to stand out in the competitive market.